Tanks

Anka Makine has long years of experience in manufacturing stainless steel tanks for milk and Dairy processing. Anka Makine supplies custom-made vessels for all Dairy milk process stages (both for farms and for dairies), including Stainless steel Dairy Bulk milk coolers, Dairy storage Silos up to 250 m3, Dairy Aseptic tanks, Dairy Fermentation tanks, Yogurt tanks, Cream tanks & Vessels, CIP tanks and road tankers. Anka Makine Dairy tanks and Vessels can be supplied complete with fully welded insulation and cladding, dimple/half pipe cooling jackets and integrated agitators, etc. All Anka Makine Dairy Silos and Dairy Vessels are finished to food grade finish in accordance with the 3A standard, and supplied to customers with relevant certifications, such as TUV or CE on demand.

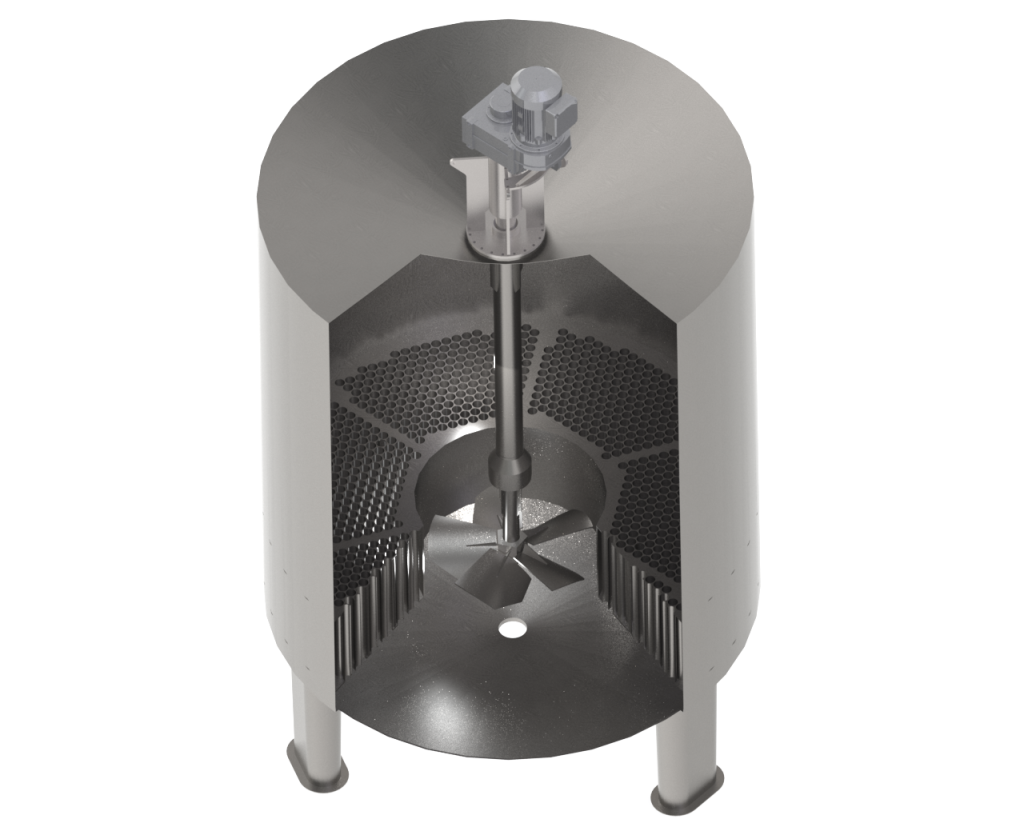

Agitators

Our agitators have a flexible, modular design and enable you to tailor a mixing solution to your exact requirements. The agitator range includes top-mounted units, with or without bottom support, as well as bottom or side-mounted units. Modularity lend itself to ease of installation and maintenance, and superior design ensures quality, performance and economy. The purpose-built agitators have smooth surfaces that promote optimal flow. Our agitators are configured to suit your process and application. Please refer to our products page for our full line of industrial agitators or proceed directly to our mixer inquiry page if you would like to engage our mixer engineering directly. We strive to understand your product and process needs so that we can custom engineer an agitator and mixer accordingly. Our understanding of your chemical product & industrial process ensures that your mixer will become part of a solution and a core capability in your process. This relationship with our clients allows us to extend our unique Solution Assurance on many of our products

Homogenizers

Anka Makine Mixer Homogenizers are fast and efficient and are capable of producing a fine droplet or particle size, typically in the range of 2 – 5 microns. This degree of homogenization is suitable for the vast majority of products, such as creams and ointments, lotions, sauces and flavor emulsions. Anka Makine offers a range of in-tank and In-Line mixer homogenizers for these applications. The precision-machined Anka Makine workhead generates exceptionally high shear rates in a three stage process that rapidly homogenizes the product to the required uniformity. For the few applications that demand submicron particle or globule sizes a high-pressure homogenizer may be required. Where this is the case, passing the product through a high shear Anka Makine Mixer Homogenizer first will dramatically improve throughput, process efficiency and reduce operating costs. This is because a high-pressure homogenizer works better when fed with a premix of uniform and fine globule or particle size, allowing the product to pass through the homogenizer at a much faster rate, normally in a single pass.

Mixers

At Anka Makine you get more than a mixer…you get mixing solutions. We know that the mixing challenges of the food and beverage industry are unique and constantly changing. That’s why our experts will work with you to make sure you get the right mixer for your specific use. Whether you’re concerned with reducing production times, process hygiene, powder/liquid mixing, producing stable emulsions, dissolving sugar, disintegrating solids, blending liquids of different viscosities or dispersing and hydrating gums, thickeners and stabilizers, Anka Makine has a mixing solution for you. We have a wide range of high shear food mixers available that are ideal for food applications, and unlike other equipment suppliers, Anka Makine has the flexibility to custom design and build machines to meet your exact specifications. So whether your application is dressings and sauces, yogurts, baby foods, jellies and preserves or a host of others, we can help you get it right the first time.

Emulsifiers

Add oil to water and the two liquids will never mix. At least not until an emulsifier is added. Emulsifiers are molecules with one water-loving (hydrophilic) and one oil-loving (hydrophobic) end. They make it possible for water and oil to become finely dispersed in each other, creating a stable, homogenous, smooth emulsion.